Mount Ceder Farm’s Transition to Paperless Systems

Initiation (2021): The journey began in 2021 when Mount Ceder Farm Management sought to revolutionize their operations by adopting a paperless system. This initiative aimed to automate data capturing to eliminate redundant work and provide management with real-time data access.

Impact on Operations: The transition to digital processes significantly enhanced the quality of the olives, streamlined the sales department’s operations, and enabled quicker stock level assessments with minimal labor required.

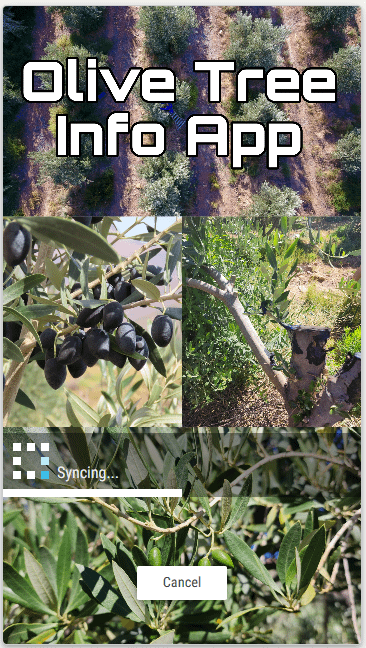

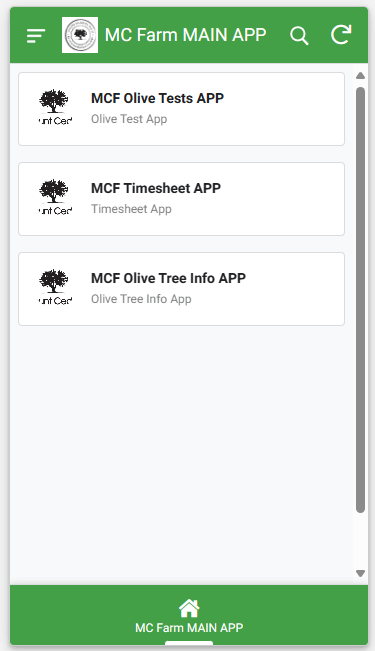

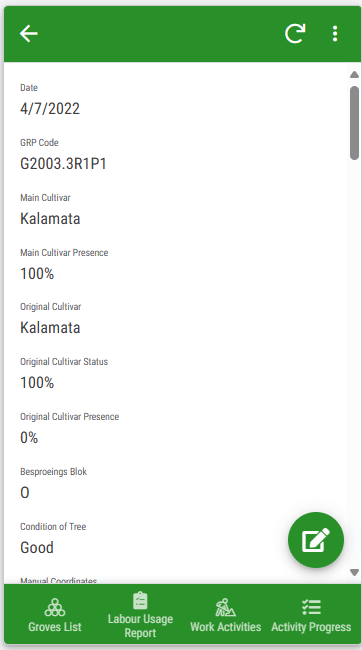

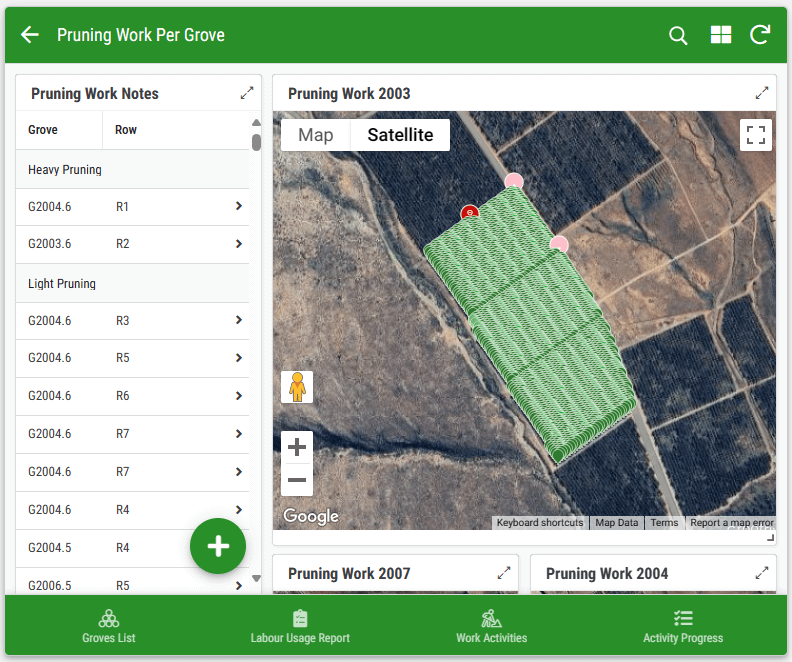

Expansion of Digital Solutions: Initially starting with a single system, the scope expanded to include various Standard Operation Procedures (SOPs) and customized applications, such as Harvesting Apps and Work Tracking Apps.

Ongoing Development: Over the last three years, Mount Ceder has continued to evolve, progressively becoming a data-driven agricultural entity, with ongoing developments to further integrate data-driven decision-making into their farming practices

Before Optimizations

Operations

- Tank testing conducted with results on paper, lacking quality tracking and manpower.

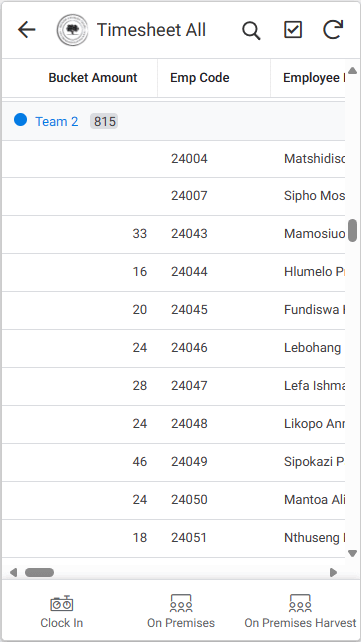

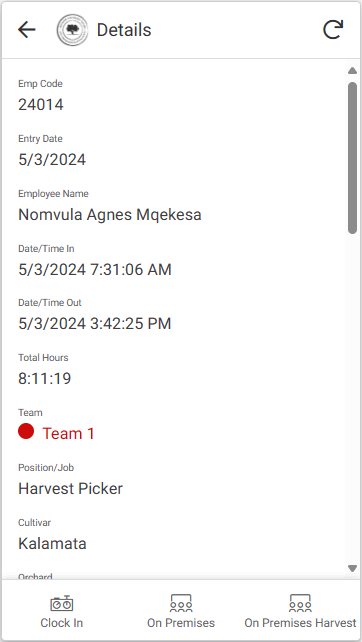

- Timesheets and bucket data captured with outdated hardware, prone to numerical errors.

- Delayed reconciliation between orchard and store during harvest season.

- No progress tracking, leading to data overload for manpower.

- Excel files exchanged via email between Paarl factory and Cederberg olive farm, causing data loss.

- Difficulty in determining stock levels due to paper systems and lack of digital input.

- Inadequate quality control and tracking at olive stores.

Human Resource Aspect

- High pressure on supervisors during harvest season (100 workers per supervisor).

- Outdated and lacking Standard Operational Procedures.

- Permanent staff burdened with excessive responsibilities, especially during harvest.

Marketing

- No activity on social media platforms.

- No presence on Instagram or LinkedIn.

- Inactive Facebook page.

After optimizations

Operations

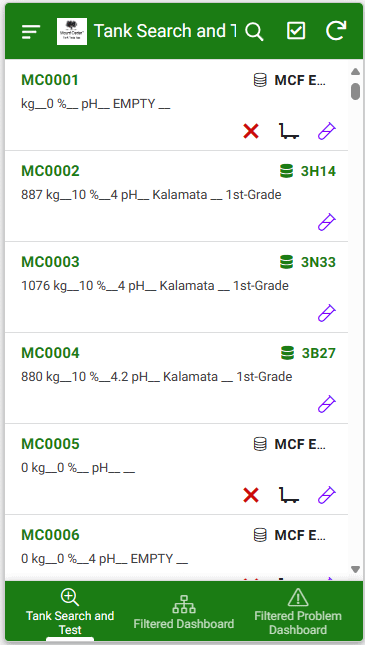

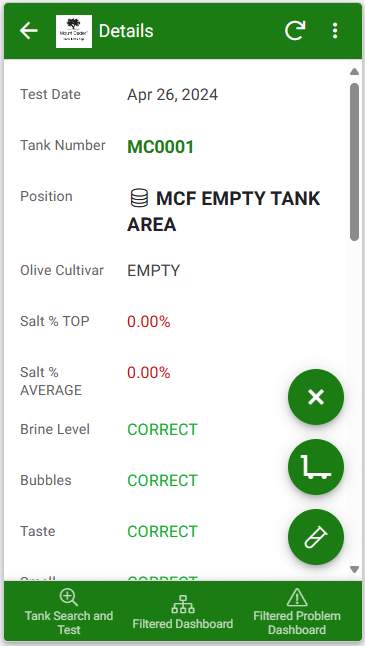

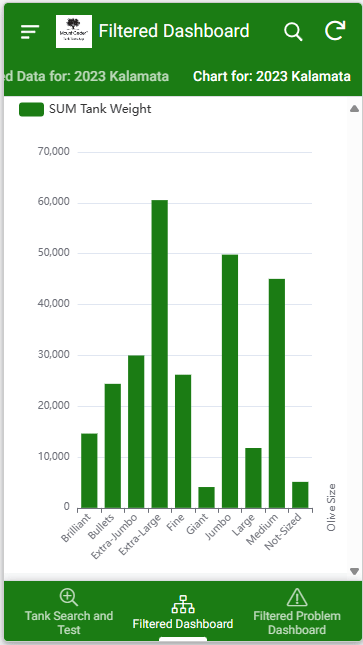

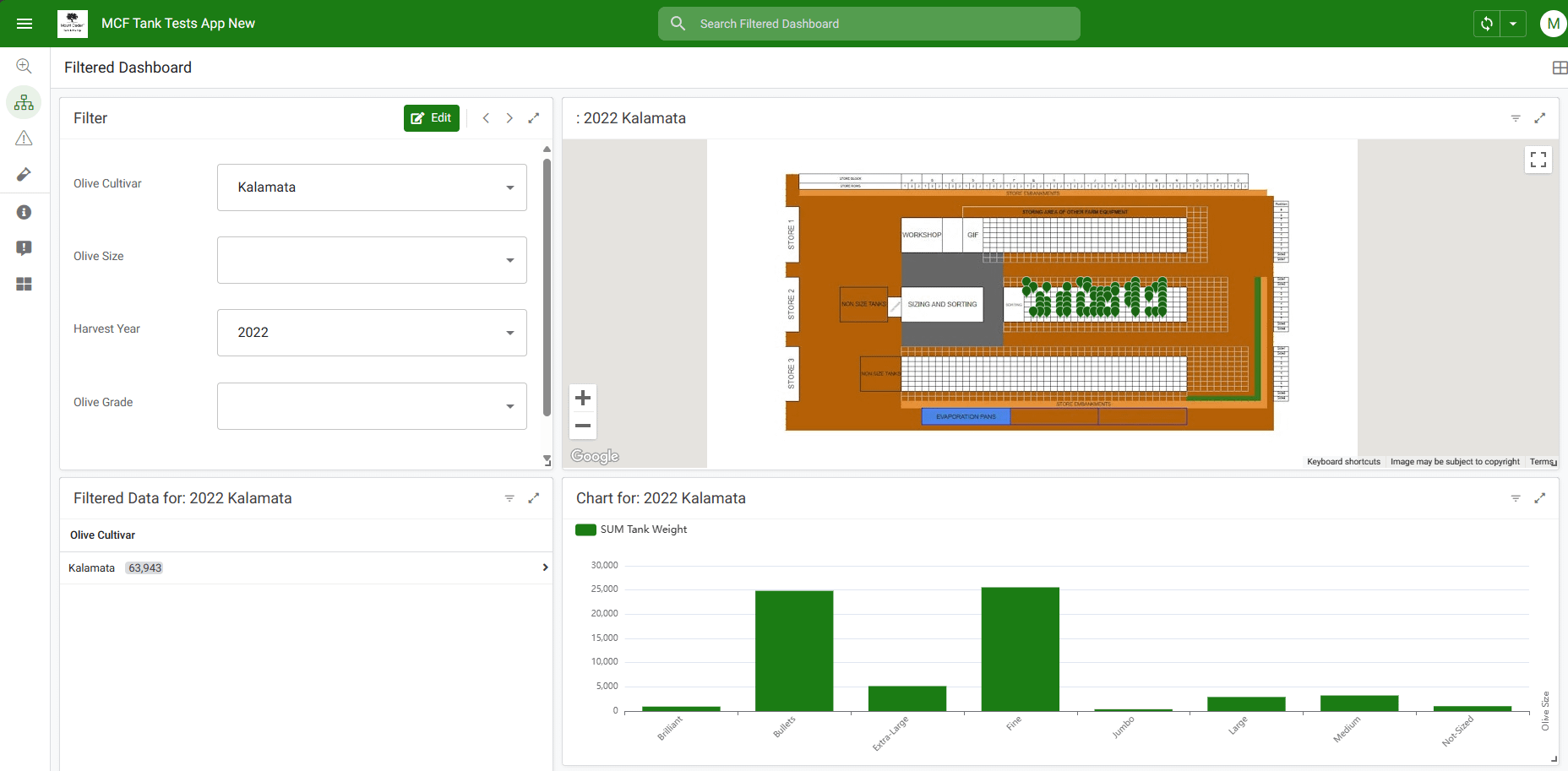

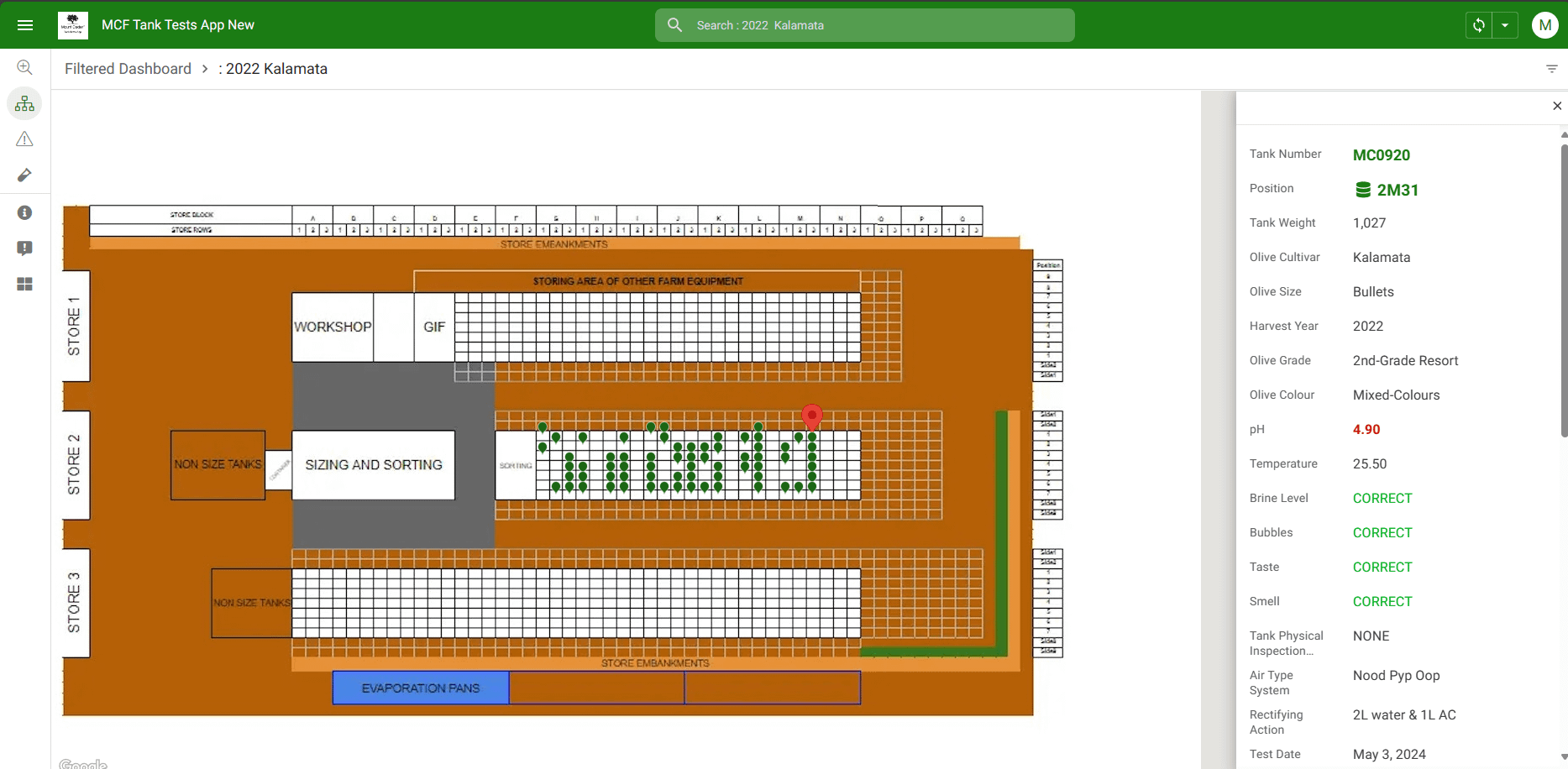

- Tank testing facilitated through customized mobile app.

- Real-time tracking of olive tanks in fermentation process.

- Harvest origin tracking of tanks implemented.

- Real-time stock level determination.

- Historical stock level data for financial reconciliation.

- Quicker finalization of bulk sales and contracts with real-time stock levels.

- Faster determination of olive size profiles through data analysis.

- Collaboration between factory in Paarl and farm facilitated with live data on Google Sheets.

Harvest Operations

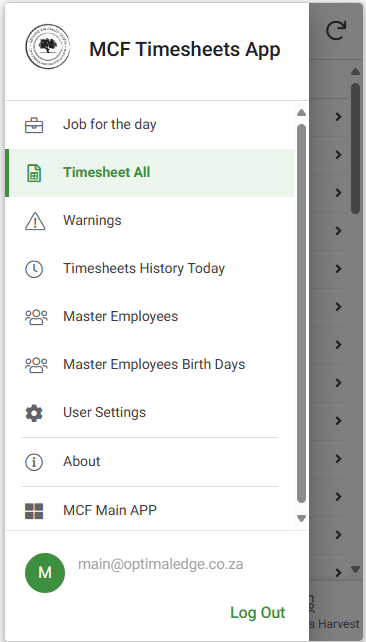

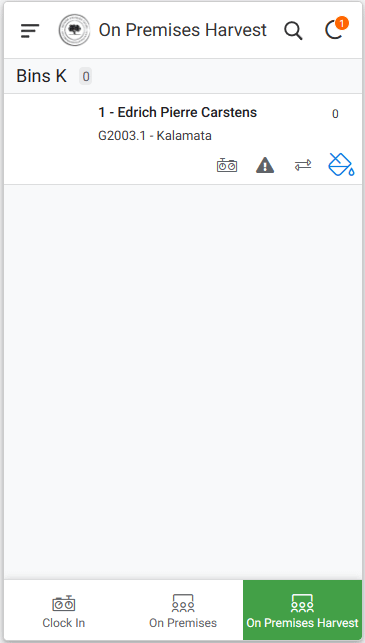

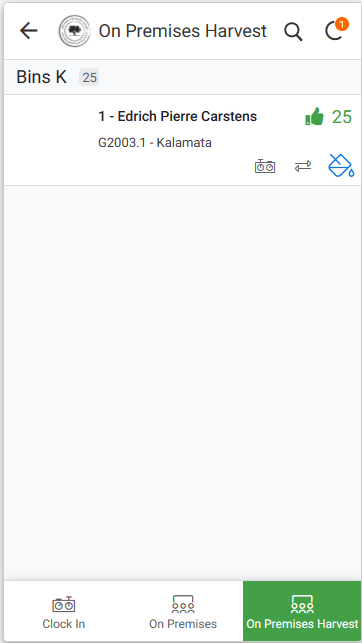

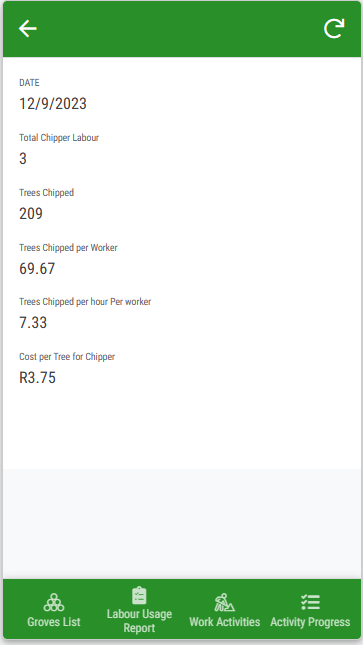

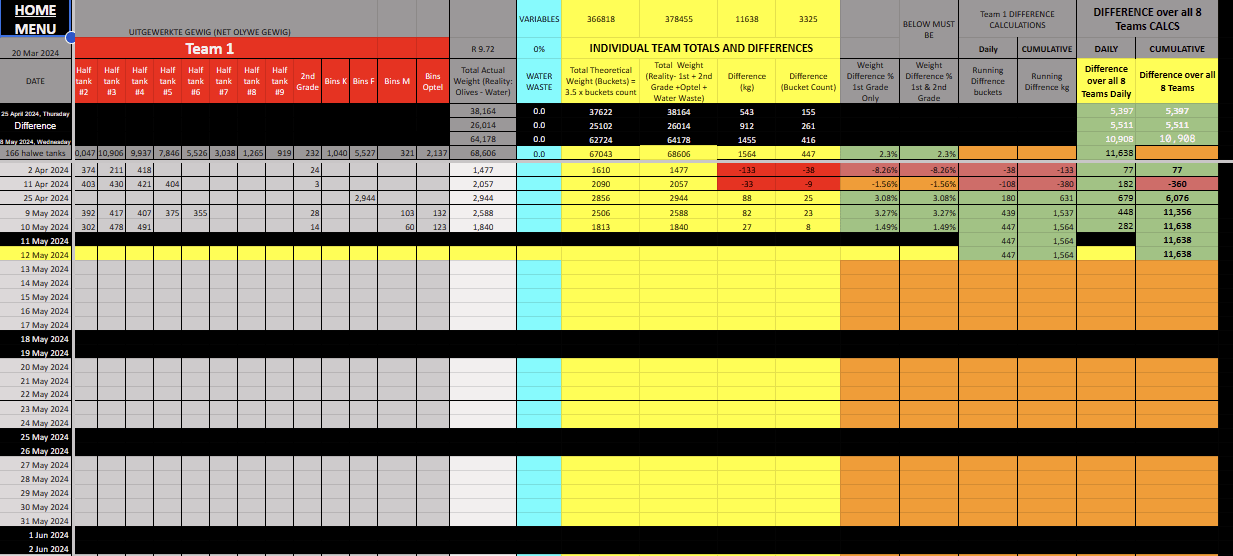

- Digital input of harvest buckets.

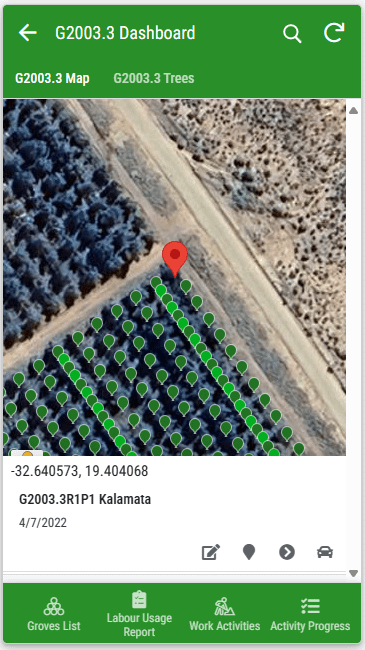

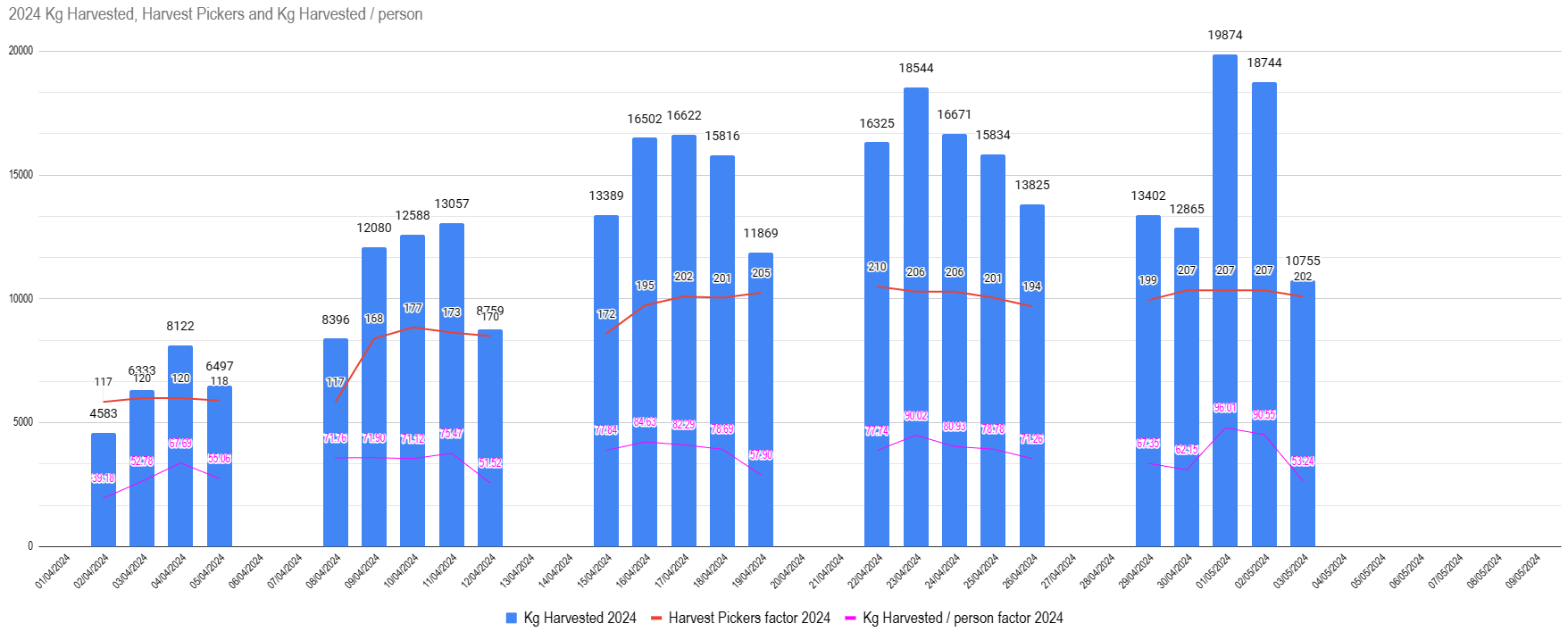

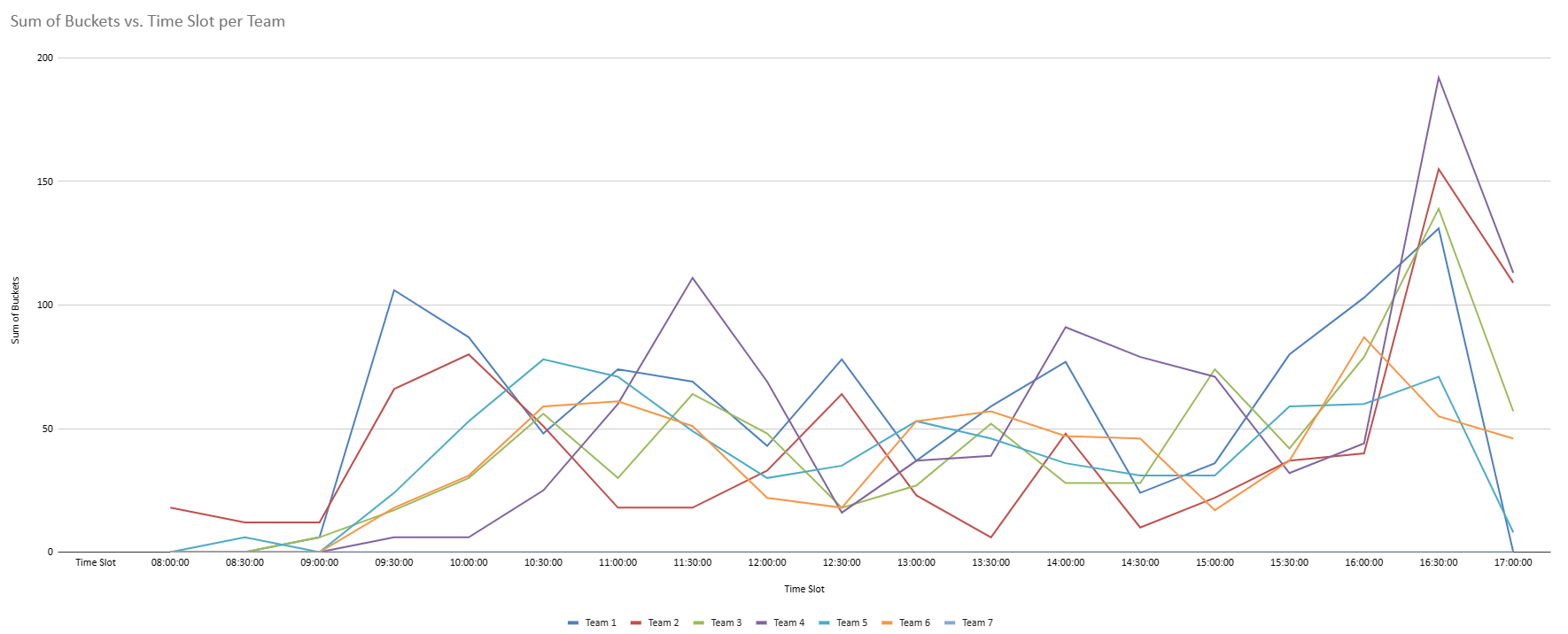

- Real-time harvest tracking.

- Significant improvement in reconciliation accuracy between stores and orchard.

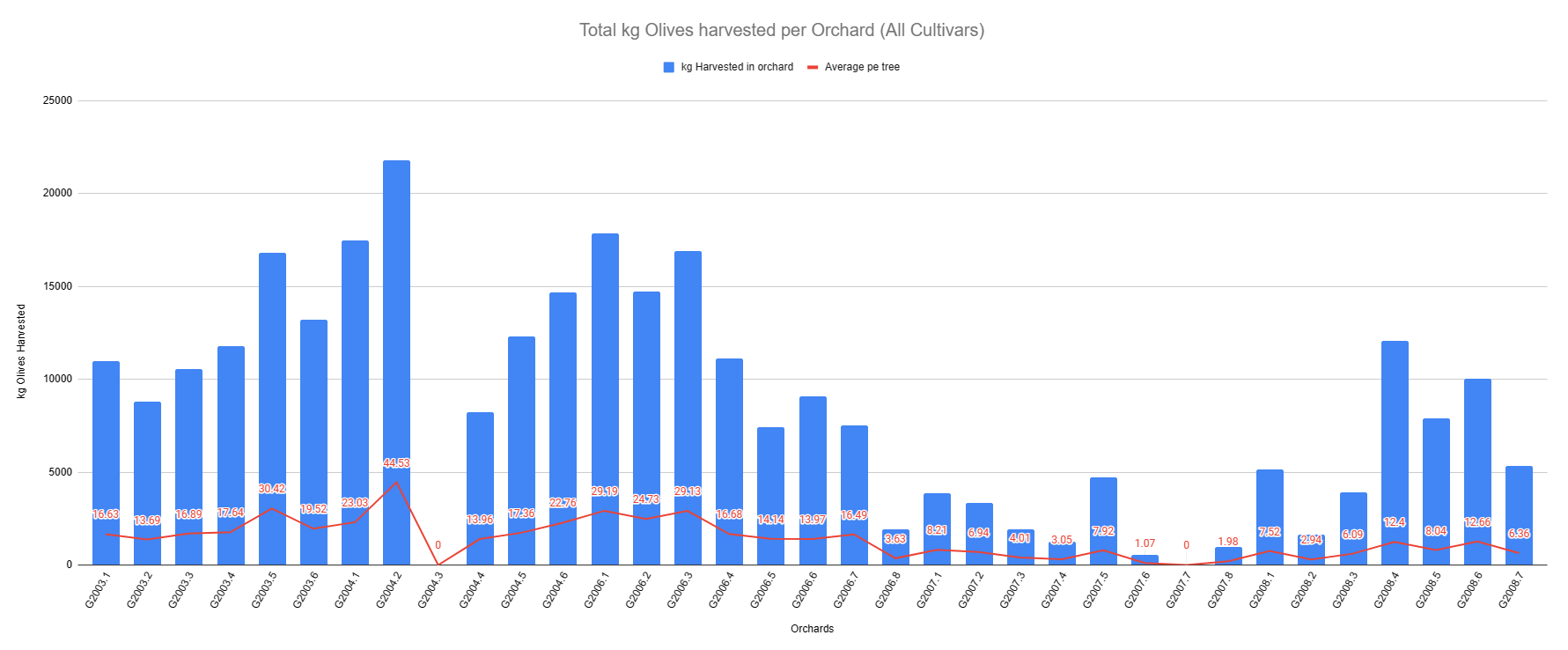

- Enhanced budgeting through more accurate data.

- Better maintenance planning based on accurate orchard yields.

- Identification of factors influencing harvest team productivity.

- Continued use of hardware for timesheet and bucket capture.

Out of Harvest Season Activities

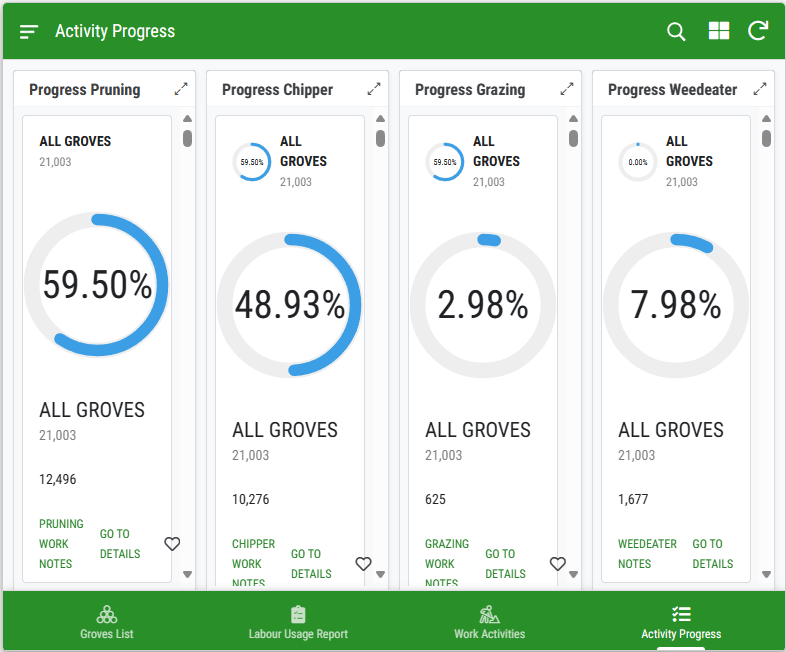

- Intensive tracking of pruning, pipe cleansing, sheep grazing, etc., with minimal input.

- Each tree connected to a history of activities, improving management efficiency.

- Improved performance management with data-driven insights.

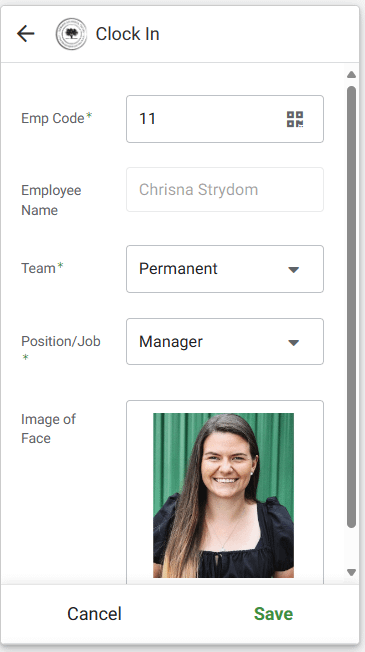

Human Resource and Administrative

- Farm and factory operate on synchronized databases, facilitating joint decision-making.

- Technology implementation provided more work opportunities while enhancing quality.

- Incentivization for accurate information led to increased continuity in the workforce.

- 300% increase in productivity after proper induction training.

- Significant increase in average kg per person per day.

- Harvest season duration reduced despite constant workforce, attributed to productivity gains.

- Updated Standard Operational Procedures and improved induction training.

- Empowerment of workforce through technology and training.

Marketing

- Active presence on social media platforms:

- Creation of Instagram and LinkedIn accounts.

- Resumed active posting on Facebook, leading to increased brand awareness and client engagement.

OPTIMIZE YOUR BUSINESS WITH US