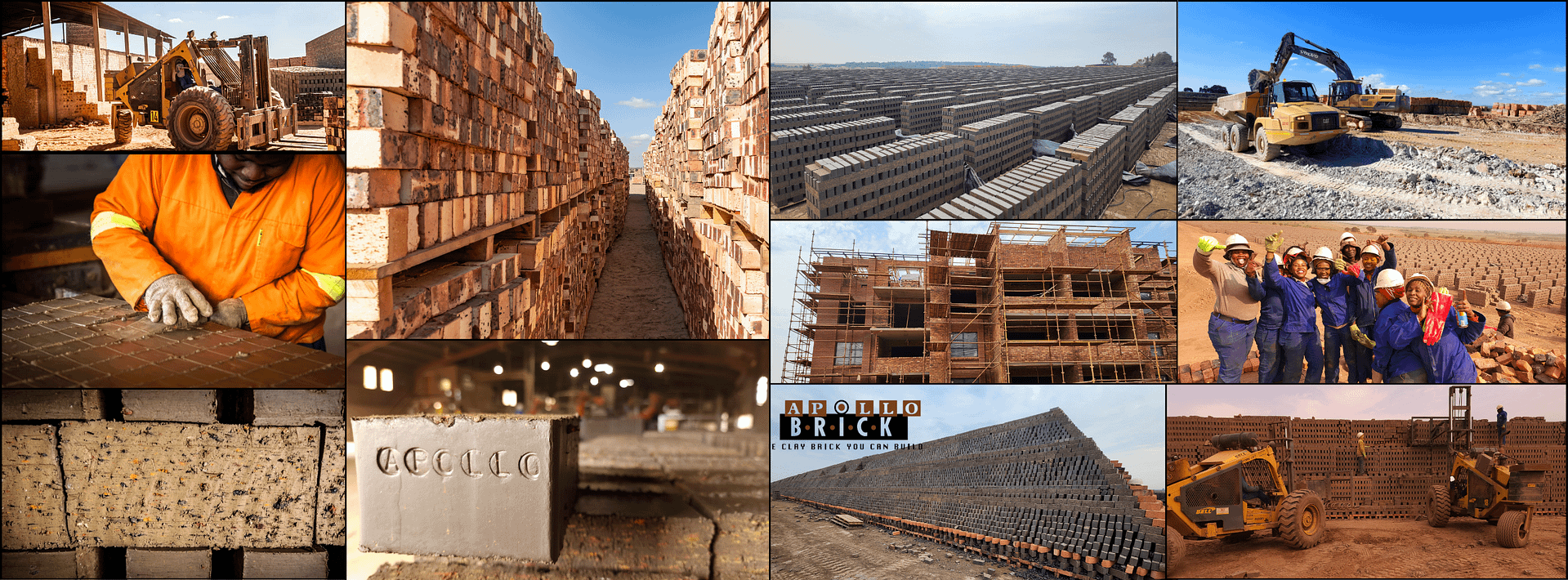

Apollo Brick’s Transition to Paperless Systems

Project Initiation (2021)

- Objective: Collaborate with Apollo Brick Western Cape to expand and roll out paperless systems to the Gauteng Branch.

- Goal: Transition to a paperless system while maintaining a focus on workforce empowerment and traditional brick-making methods.

Project Challenges and Approach

- Realistic Priority Adjustment: At Optimal Edge, we adjust project priorities to achieve short-term wins that lead to long-term success.

- Starting Point: Gate Control Automation was prioritized to streamline truck departures, transitioning from manual photo records to automated emails.

Other General Advancements

- Pearish Clamp Timesheets: Improved structuring before automation.

- Dryer Department: Expanded and structured information intake.

- Apollo Brick Lab: Optimized information intake, creating valuable data comparisons for all departments.

- Worker Upliftment: Promoted workforce empowerment and spirit upliftment through events and skill development.

Ongoing Development

- Template for Gauteng Branch: Western Cape Branch serves as a model for implementation in Gauteng.

- Underlying Business Principles: Despite structural differences, the business model principles remain consistent.

- Focus on Empowerment: Value placed on advancing and empowering the workforce through systems and problem-solving.

Before Optimizations

Operations

- Data was captured manually on paper and required administrative departments to input this data into systems.

Human Resource Aspect

- Heavy reliance on administrative staff for data entry and management.

Marketing

Apollo Brick did not have a dedicated marketing department.

After optimizations

Operations

- Employees directly input data into the system, reducing redundancy and increasing data accuracy. The system flags skewed data for management review, streamlining operations and improving decision-making.

Human Resource and Administrative

- Employees are empowered to handle data entry, reducing the administrative burden. The system’s automated processes ensure that data is captured accurately and efficiently, improving overall productivity.

Marketing

- Optimal Edge assisted in creating Instagram, Facebook, and LinkedIn accounts for both branches. This led to significant growth, with sales increasing from 150k per day to almost 250k on average. The combined efforts of systems development, operational improvements, and media presence contributed to this growth, enhancing both production and sales.

Key Developments

Automated Data Capturing:

- Initial idea evolved into full operational movement.

- Analyzed current operations and systems.

- Designed new data capturing processes, ensuring paper-based systems worked before implementing technology.

Impact on Operations:

- Engaged with various departments: Maintenance, Pearish Clamps (ovens), Dryers, Extrusion, Milling, and Mining.

- Steps included understanding current structures, identifying data value, and designing improved data capturing processes.

Change Management and Training:

- Adapted systems to the intellectual and educational levels within the organization.

- Implemented change management, ongoing training, and workforce skill improvement.

System Implementation and Continuous Improvement:

- Example: ABC Gate Control system transitioned from a paper-based system to an automated notification system.

- Continuous updates based on identified variables and challenges.

Expansion of Digital Solutions

Health and Safety System:

- Captures injury reports and notifies the OSEH officer.

- Generates FEM documents for hospital use quickly.

Yard/Timesheets Application:

- Covers various production and maintenance areas across the 64-hectare grounds.

- Includes Oven Check sheets, Timesheets logging, and statistical counts of ovens.

Maintenance Application:

- Manages mobile plant check sheets and service job cards through a structured process.

- Integrated with Health and Safety, Maintenance, and Yard Applications.

Extrusion and Milling Application:

- Logs plant downtime and production.

- Integrated with Health and Safety, Maintenance, and Yard Applications.

OPTIMIZE YOUR BUSINESS WITH US